Jamdani

ETYMOLOGY AND ORIGIN :

The etymology of 'Jamdani' reveals a fascinating cultural heritage, derived from the Persian words 'Jam' signifying flower and 'Dani’ denoting container or vessel. This ancient textile art form was introduced to Bengal by Mughal emperors in the early 17th century, who brought skilled artisans from Persia (modern-day Iran) to cultivate this exquisite craft.

Under the auspices of royal patronage, Jamdani production flourished, with master weavers creating intricate, florid and baroque designs for the Mughal court. The city of Dhaka, situated in the heart of Bangladesh, emerged as a preeminent centre for Jamdani production, renowned for its superlative quality and craftsmanship.

The Migration of the craft :

The Jamdani textile tradition has experienced a significant transnational journey, moving across geographical and cultural landscapes from its origins in Bangladesh to its modern expressions in Bengal. This transition is closely associated with the 1947 Partition of India, which fragmented the Indian subcontinent into East Pakistan (now Bangladesh) and West Bengal (India). The migration of artisans, particularly Jamdani weavers, from East Pakistan to West Bengal profoundly influenced the development of Jamdani textiles.

As these artisans established themselves in Bengal, they introduced their traditional methods, designs, and skills, which played a crucial role in revitalizing and transforming Jamdani textiles in the area. The cultural interchange between Bangladeshi and Bengali artisans allowed for the adaptation of traditional Jamdani motifs to align with local aesthetics, creating a distinctive fusion of cultural elements.

Today, Bengal boasts a vibrant Jamdani industry, where artisans persist in innovating and refining traditional techniques. The Bengal Jamdani has forged a unique identity, harmoniously merging traditional Bangladeshi designs with regional Bengali influences. This extraordinary amalgamation has given rise to a textile tradition that reflects the rich cultural legacy of the region.

Techniques :

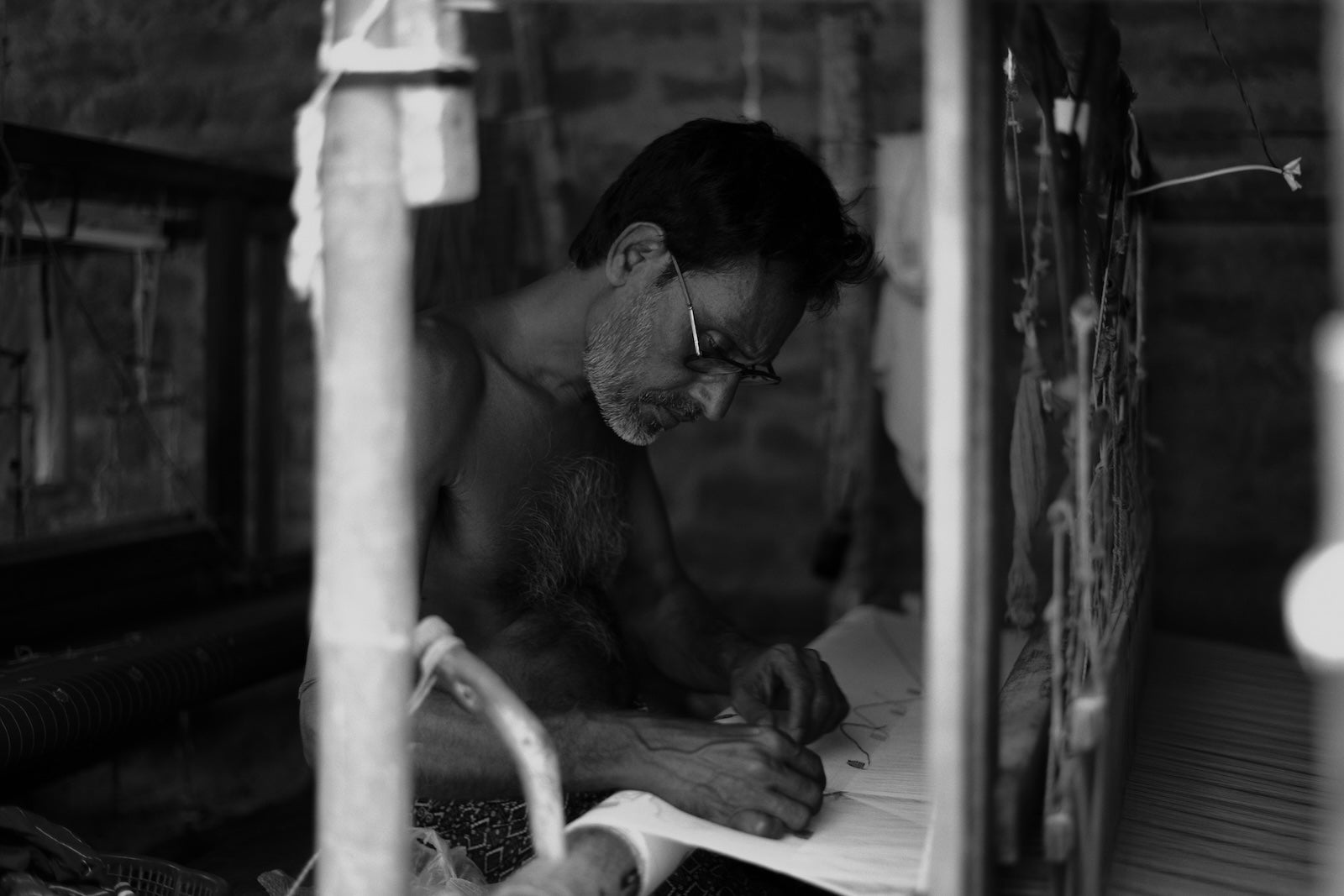

"The artisanal expertise in weaving Jamdani textiles was contingent upon the precise skill of yarn production, which was optimally executed during the early morning hours when ambient humidity levels were conducive to superior yarn quality. Traditional Jamdani weavers employed an array of bespoke tools, including bamboo baskets, shells, and stone cups, to facilitate the starching process, which utilized starch derived from popcorn, rice, or barley.

Prior to initiating the intricate Jamdani patterning process, artisans would meticulously dye and starch the yarn using natural dyes extracted from flora, such as flowers and leaves. The production of high quality Jamdani textiles necessitated yarn counts ranging between 200 and 250. In contemporary practice, however, many weavers have opted to purchase fine yarn and employ chemical dyes in lieu of traditional herbal alternatives. The intricate Jamdani designs are painstakingly crafted by two skilled weavers working in tandem at a loom, utilizing coarse yarns to elevate motifs above the fabric. Initially, Jamdani textiles featured gray backgrounds, but later evolved to incorporate a diverse array of colors, with red fabric gaining particular popularity during the 1960s."

Steps of Jamdani Weaving:

Design Planning: The design for the fabric is first sketched by the artisan, often using traditional motifs like flowers, geometric patterns, or paisleys. This design is then translated into a paper pattern (or graph), which guides the weaving process. Thread Dying : Thread dyeing is an essential process in textile manufacturing where yarns or threads are dyed before they are woven or knitted into fabric. This process ensures that the final fabric has consistent colour and can be crafted into intricate patterns, especially in handwoven textiles(like Jamdani).

Warping: The warp threads (the longitudinal threads that run vertically) are prepared by winding them onto a loom. This process can take several hours, as the threads are arranged carefully to ensure the right tension for weaving.

Threading the Loom: The warp threads are passed through the loom. In traditional Jamdani weaving, the loom is often a handloom, where the artisan manually controls the weaving process.

Weaving:

Weaving the Weft: The weft threads (horizontal threads) are manually inserted into the warp threads. This is where the Jamdani technique shines. The artisan inserts extra threads to create patterns, sometimes using multiple wefts in a single row to form intricate designs. These threads are woven intermittently to create the distinctive brocade effect on the fabric. Weft Inlaying (Jamdani work): For decorative elements, the weft threads float over multiple warp threads or are “dropped” to form detailed patterns. These patterns are created directly on the loom, often without using any machines, making the process the most time-consuming and labour-intensive.

Finishing: After the weaving is complete, the fabric is washed to remove any starch or impurities. The fabric may also be pressed and finished to give it a smooth, crisp feel.

Design Principle

The distinctive hallmark of Jamdani work lies in its intricate geometric patterns, which skilled artisans create with intuitive precision, eschewing preliminary sketches. Each design boasts its own unique nomenclature, such as Panna Hajar, Dubli Jal , Hazar buti , Korat Noksha Kaj and Mayur Pyanj among numerous others. This rich design lexicon reflects the artisanal expertise and cultural heritage underlying Jamdani production.

In contemporary iterations, Jamdani saree often showcase background designs inspired by natural elements, such as roses, jasmine and lotus. This blending of traditional craftsmanship with modern aesthetics exemplifies the dynamic evolution of Jamdani artistry, as artisans adeptly navigate the intersection of heritage and innovation.

A Paradigm of Craft and Cultural Preservation : Gulmohar’s Commitment

Gulmohar's organisational culture is deeply rooted in a profound reverence for the artisanal expertise indigenous to rural Bengal. By cultivating symbiotic relationships with local artisans, the brand fosters an atmosphere of mutual respect, trust, and creative collaboration. This harmonious partnership enables Gulmohar to harness the artisans' innate talents and knowledge, culminating in the creation of exquisite Jamdani textiles that honour the region's rich cultural heritage.

Our commitment to community development is evident in its multifaceted initiatives aimed at enhancing rural livelihoods. By providing artisans with stable income opportunities, training, and capacity-building programs, Gulmohar plays a pivotal role in the socioeconomic empowerment of marginalised communities.

Sustainability is a core principle of Gulmohar's philosophy, as demonstrated by its commitment to environmentally responsible practices. The brand's adoption of natural dyes, organic cotton, and sustainable production methods exemplifies its dedication to reducing its environmental footprint. By embracing a comprehensive approach to sustainability, Gulmohar fosters a more conscious and responsible fashion industry.Through its community-focused initiatives, dedication to preserving the Jamdani craft and commitment to sustainable practices, Gulmohar has established a paradigmatic model that empowers rural artisans, celebrates cultural heritage and promotes environmental responsibility.